True to the optical axis

Topics covered in the article:

- Description of the working principles of alignment turning

- Application and design guidelines for objective lenses

- Special lenses (aspheres and cylinders)

- Large optics (>200 mm diameter)

- Active components

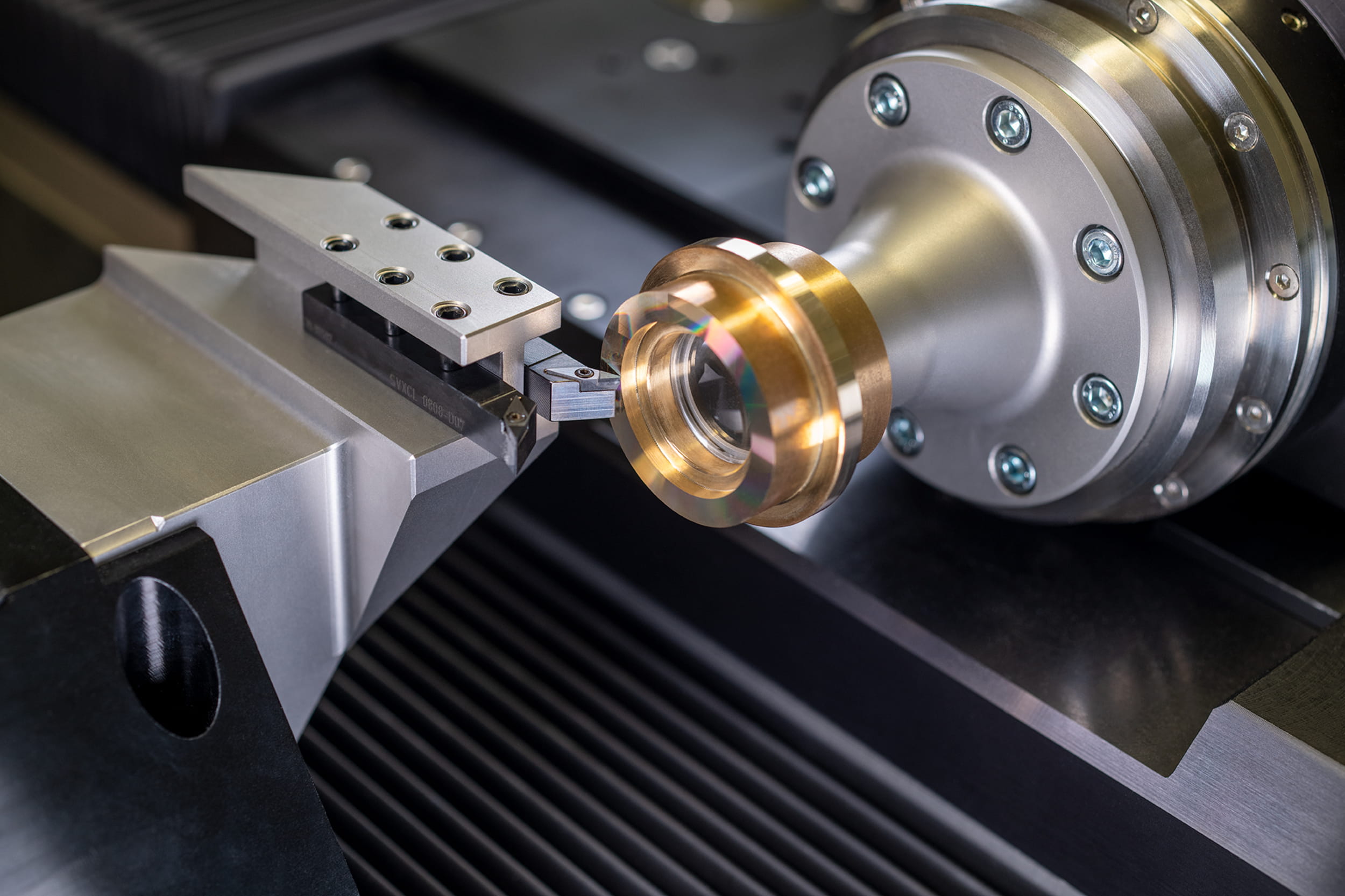

High-precision alignment and machining of mounted lenses

The demand for high-precision optical manufacturing technologies is increasing. This includes the need to align passive optical elements such as single lenses and lens systems as well as active optical elements such as laser diodes. For passive and active optical components, alignment turning meets the increasing industrial requirements for precision, freedom of design, automation, and competitive production times.

The TRIOPTICS ATS alignment turning machine combines the proven OptiCentric® centration measurement system with an ultra-precise turning machine. This makes it possible to adjust and control all relevant parameters while processing the mount, such as diameter of the mount or the distance of the lens from the contact surfaces of the mount.

Strong trust in our expertise

Product Overview

The ATS family consists of several product variants. They differ both in the maximum work piece size that can be machined and in their accuracy. All variants can be set up efficiently and allow machining of medium and small batch sizes. In addition, individual customizations are possible as well.

ATS 100

Cycle time-optimized processing of large batch sizes for life science optics such as microscope and endoscope objectives as well as camera systems

- Work piece diameter: up to 100 mm

- Manufacturing accuracy: 2.5 µm

- Optional laser diode turning and center thickness measurement

ATS 200 and 200 UP

Flexible use for numerous applications

- Work piece diameter: up to 200 mm

- Manufacturing accuracy: up to 0.5 µm

- Optional asphere measurement and center thickness measurement

ATS 300 UP

High-precision alignment turning station for the semiconductor industry

- Work piece diameter: up to 300 mm

- Manufacturing accuracy: 0.5 µm

- Optional asphere measurement and center thickness measurement

About TRIOPTICS

TRIOPTICS - a member of the Jenoptik photonics group - is an international company, specialized in optical metrology and production technology. It’s expertise ranges from the testing of individual optical components to the assembly and testing of complex optoelectronic systems. TRIOPTICS products are used in all sectors that deal with the production, inspection, and application of optical assemblies.

30 years of expertise in optical measurement and manufacturing technology

Specially selected global project teams with many years of eperience

Installation and service worldwide

Short development cycles - all relevant divisions "inhouse"

Complete solution from one source

Scalable metrology across the entire optical value chain